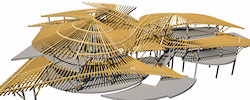

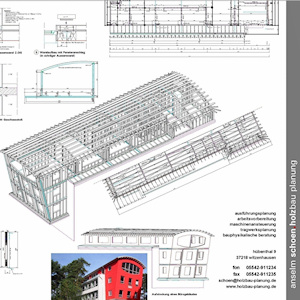

Engineered wood construction

Nowadays, the majority of engineers in the field of timber construction globally work with cadwork. All of them are thrilled by its boundless flexibility in 3D design. Completely unrestricted and creative work with wood, steel, concrete and other materials enables them to plan, design and realise the most spectacular projects we know. You can find a selection of them in our client projects.

Unrestricted design in 3D

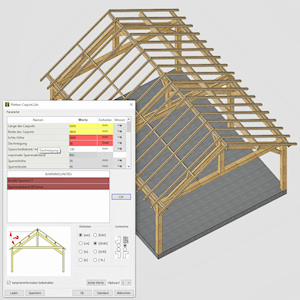

cadwork is the only software specialising in wood construction which adapts to designers‘ needs and requirements, not vice versa. Our software solution offers a high grade of automisation whenever you wish. Following any automated solution, cadwork’s principle of being able to edit all generated components without restrictions applies. This combination allows you to be extremely fast while maintaining complete control over your design process.

In engineered wood construction you will regularly want to insert, move, copy, stretch or cut component by component and connector by connector, or add features to them one by one. Even complex tasks in engineered wood construction can easily be accomplished intuitively after only a short familiarisation period.

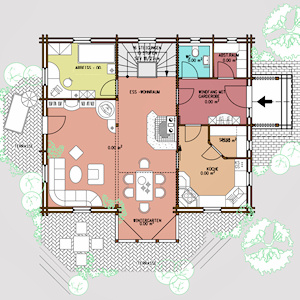

Cross-trade project handling in the BIM process

Planning, design and construction of a building inevitably involves several trades. Therefore, it has always been one of cadwork’s top priorities to facilitate the smooth collaboration of professionals from different trades. Our certified IFC 2×3 import and export within the BIM process is proof of this. In addition, cadwork supports IFC 4.

With its Multi-IFC Management, BMT, Attribute Mapping and BCF our BIM Manager offers comfortable, modern tools for working with BIM.

File formats such as SAT and STEP along with native interfaces with Rhinoceros and Revit offer further options to import and export 3D data.

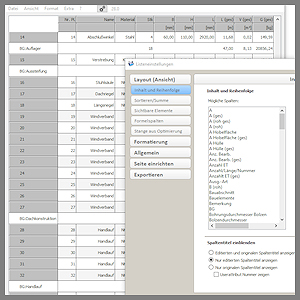

Manufacture of glulam

Most glulam manufacturers worldwide work with cadwork. By using the same software as your suppliers you, too, can benefit from the resulting synergy. Simply communicate your straight or uniaxially curved building components to a cadwork client using our Lamella module. In no time at all they will generate the lamella list and press bed in order to produce and deliver your perfectly fitting pieces of glulam.

The cadwork modules used in this solution